Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyProject video »BTfly«

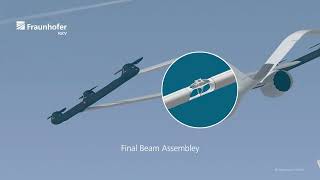

The BTfly project is specifically concerned with biological transformation applied to components of electrically powered aircrafts. The early phase of product development enables the product and production processes to be co-designed according to aspects of sustainability and biological transformation. There is a high degree of creative freedom in the design of the flying objects, and thus the possibility of approaching optimization by integrating structures, principles, and materials from nature into technology.

To exploit the full potential of biological transformation, holistic approaches are required that consider aspects of sustainability along the entire life cycle of the product. However, ecological sustainability is often in conflict with economic concerns and component performance; therefore, products usually represent a compromise solution based on a selective and not least subjective decision-making process.